Rubber floor sheets are becoming a preferred choice across a wide array of industries, from bustling gyms to heavy-duty industrial facilities. Known for their exceptional durability, safety features, and eco-friendly options, these versatile flooring solutions are designed to handle the toughest demands while meeting modern sustainability standards. Whether you need shock-absorbing surfaces for fitness spaces or slip-resistant flooring for high-traffic environments, rubber floor sheets provide a reliable and efficient foundation. In this blog, we’ll explore their types, practical applications, and maintenance tips, showcasing why they’re the go-to flooring solution for diverse environments.

Table of Contents

Benefits of Rubber Floor Sheets

Rubber floor sheets have gained traction across industries thanks to their impressive combination of practicality, durability, and safety. They offer a highly functional and long-lasting solution for flooring needs, making them a preferred choice for gyms, industrial facilities, healthcare environments, and beyond. Here’s an in-depth look at the key benefits that make rubber floor sheets invaluable.

1. Exceptional Durability

Rubber floor sheets are built to last, even in high-traffic or heavy-duty environments. Their resilience to wear and tear ensures that they can endure constant foot traffic, heavy equipment, and repetitive impacts without cracking or deforming. This makes them a cost-effective investment for facilities that prioritize long-term performance.

Example:

Large industrial facilities often rely on rubber floor sheets to protect underlying concrete from heavy machinery damage and to maintain smooth, safe surfaces even after years of use.

2. Enhanced Safety Features

One of the standout benefits of rubber floor sheets is their ability to create a safer environment. Their non-slip surfaces reduce the likelihood of slips and falls, even in wet or greasy conditions. Additionally, rubber’s natural shock-absorbing properties cushion impacts, protecting both users and equipment.

Example:

Fitness centers use rubber flooring extensively in weightlifting areas to prevent injuries caused by dropped weights while also safeguarding the subfloor.

3. Versatility Across Applications

Rubber floor sheets adapt seamlessly to a variety of settings and purposes. They are available in different thicknesses, textures, and finishes to suit specific needs, from heavy-duty industrial zones to comfortable residential spaces. Their flexibility makes them ideal for indoor and outdoor use.

Applications Include:

- Gyms and Fitness Centers: For shock absorption and noise reduction.

- Industrial Facilities: Resistant to chemicals and abrasion.

- Healthcare Settings: Sanitary, non-slip surfaces for patient safety.

- Commercial Spaces: Attractive designs that match branding while providing durability.

4. Eco-Friendliness

With growing environmental concerns, rubber floor sheets often appeal due to their sustainable production options. Many are made from recycled materials, including post-consumer rubber products like old tires, reducing landfill waste and promoting a circular economy.

Example:

Recycled rubber floor sheets used in playgrounds align with environmental initiatives, offering safe, durable surfaces while lowering the facility’s ecological footprint.

5. Ease of Maintenance

Rubber floor sheets are incredibly low-maintenance, requiring simple cleaning routines to keep them in top condition. Their resistance to stains and moisture reduces upkeep effort and costs, which is an added advantage for facilities with heavy daily use. For even greater convenience, many rubber floor sheets come with slip-resistant coatings that reduce cleaning frequency.

Practical Maintenance Tips:

- Sweeping or vacuuming daily to remove debris.

- Using pH-neutral cleaners for occasional mopping.

- Conducting routine inspections to promptly address minor wear.

Example:

Commercial kitchens benefit from textured rubber floor sheets that are easy to clean while ensuring non-slip safety, even in high-moisture areas.

Why Rubber Floor Sheets Stand Out

Rubber floor sheets combine functionality, safety, and sustainability, making them a perfect choice for businesses and homeowners alike. Their ability to meet the unique demands of various settings—whether it’s creating a safe fitness zone, protecting industrial infrastructure, or contributing to eco-friendly goals—makes them a standout option for versatile flooring solutions. By investing in rubber floor sheets, you’re not only enhancing the durability and safety of your space but also contributing to a more sustainable future.

Types of Rubber Floor Sheets

Rubber floor sheets come in a variety of options, each designed to address specific needs, environments, and preferences. Whether for a gym, industrial facility, or commercial space, understanding the different types is key to choosing the most suitable flooring solution. Here’s a detailed look at the common types of rubber floor sheets and their unique features, benefits, and ideal applications.

1. Natural Rubber Sheets

Overview:

Natural rubber sheets are made from latex, derived from rubber trees. Known for their elasticity and durability, these sheets are highly versatile.

Key Features and Benefits:

- Excellent tensile strength, making them highly resistant to tearing and stretching.

- Soft and flexible, ideal for high-impact areas.

- Eco-friendly, as they are derived from a renewable resource.

Ideal Applications:

- High-traffic areas in industries such as automotive, where long-lasting durability is needed.

- Gyms requiring a soft yet robust surface for workout areas.

Example:

Natural rubber sheets are often used in eco-conscious fitness centers, providing shock absorption and slip resistance without compromising the environment.

2. Recycled Rubber Sheets

Overview:

Recycled rubber sheets are created from repurposed rubber materials, such as old tires. They offer an environmentally friendly option while maintaining performance.

Key Features and Benefits:

- Cost-effective compared to virgin rubber.

- Durable and resistant to wear, even in heavy-use areas.

- Contributes to sustainability by saving materials from landfills.

Ideal Applications:

- Gyms and fitness centers for weightlifting zones, thanks to their high impact tolerance.

- Playgrounds, where safety is a priority, due to their cushioning capabilities.

Example:

Recycled rubber sheets are commonly used as playground surfaces, combining eco-friendliness with enhanced safety for children.

3. Synthetic Rubber Sheets (e.g., EPDM, Neoprene)

Overview:

Synthetic rubber sheets are created using man-made materials like EPDM (ethylene propylene diene monomer) and Neoprene, offering superior resistance to challenging environments.

Key Features and Benefits:

- EPDM Sheets:

- Excellent resistance to UV rays, ozone, and extreme temperatures.

- Perfect for outdoor applications.

- Neoprene Sheets:

- Chemical-resistant and waterproof, making them ideal for industrial settings.

- Long-lasting, even in harsh conditions.

Ideal Applications:

- EPDM: Roofing membranes, outdoor flooring, and wet areas like poolsides.

- Neoprene: Industrial setups prone to chemical exposure, such as labs and processing plants.

Example:

EPDM rubber flooring is frequently installed in outdoor athletic tracks, where UV and weather resistance are critical.

4. Textured Rubber Sheets

Overview:

Textured rubber sheets are designed with special surface patterns that enhance grip and reduce the risk of slipping.

Key Features and Benefits:

- Anti-slip properties, even in wet or oily environments.

- Additional cushioning for improved comfort.

- Aesthetic versatility, as textured patterns add character to a space.

Ideal Applications:

- Commercial kitchens or warehouses where spills are inevitable.

- Healthcare facilities, ensuring safety for patients and staff in high-traffic areas.

Example:

Textured rubber sheets are ideal for restaurant kitchens, offering a safe and durable anti-slip surface to handle spills and grease.

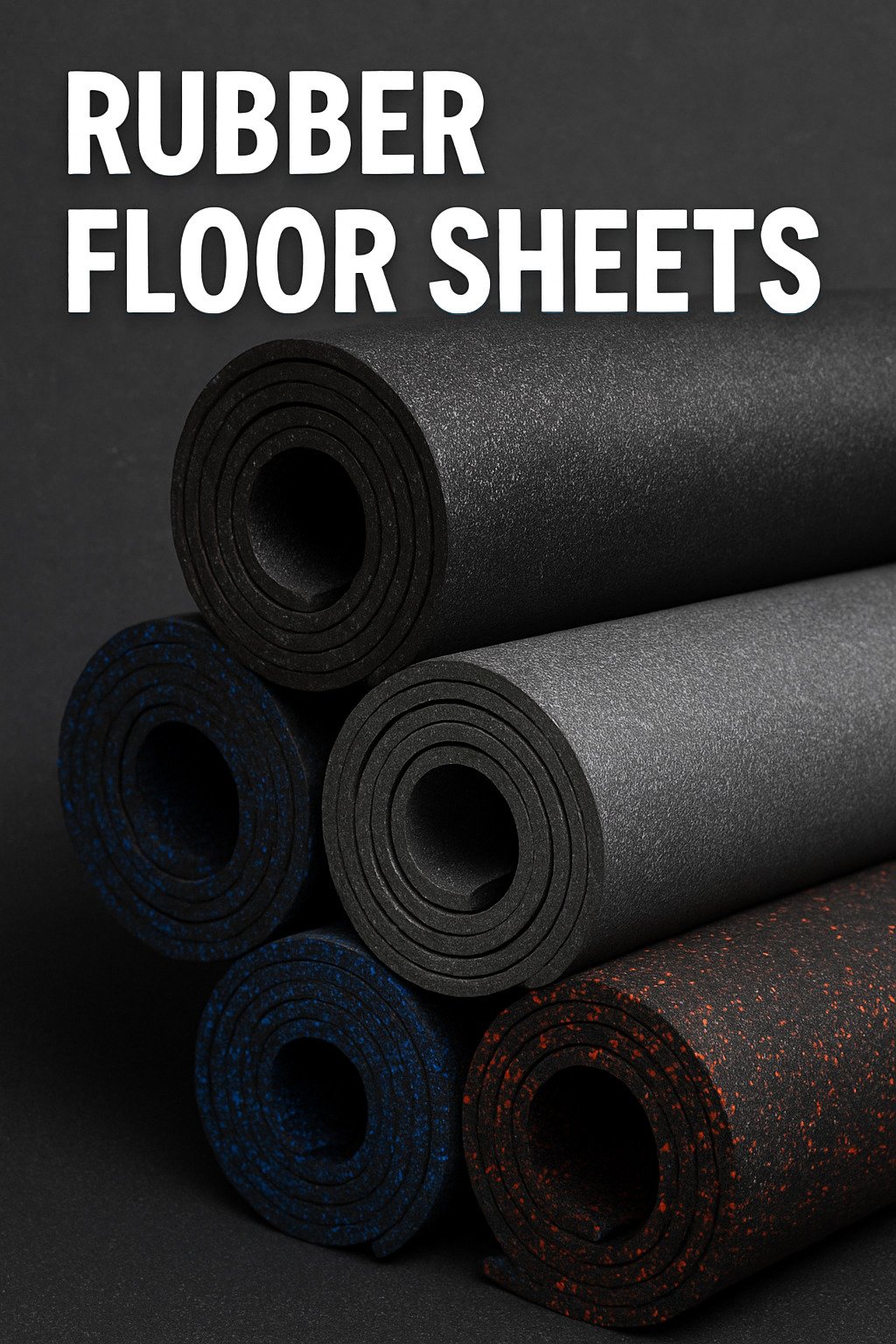

5. Rubber Mat Rolls vs. Pre-Cut Sheets

Overview:

Rubber floor sheets come in two main formats—rubber mat rolls and pre-cut sheets—each offering unique advantages depending on the intended use.

Rubber Mat Rolls:

- Features and Benefits:

- Provide seamless coverage for large areas.

- Easy to install in spacious facilities, reducing the number of visible seams.

- Ideal Applications:

- Gyms needing continuous flooring to support large workout areas.

- Factories with heavy machinery that require robust, uninterrupted coverage.

Pre-Cut Sheets:

- Features and Benefits:

- Precise sizing eliminates the need for additional cutting.

- Easier to install in smaller, irregularly shaped rooms or for localized coverage.

- Ideal Applications:

- Home gyms or spots needing strategic floor protection, such as under treadmills or workbenches.

Comparison Example:

Fitness centers with expansive workout zones often opt for rubber mat rolls to ensure seamless flooring, while residential gyms use pre-cut sheets for efficiently covering smaller areas.

Summary

Rubber floor sheets are available in multiple types, each offering distinct strengths and applications:

- Natural rubber sheets provide elasticity and eco-friendliness for high-use zones.

- Recycled rubber sheets combine cost-saving durability with sustainability.

- Synthetic rubber sheets like EPDM and Neoprene excel in harsh conditions, both indoors and outdoors.

- Textured rubber sheets enhance grip and safety in slippery environments.

- Rubber mat rolls and pre-cut sheets cater to different space requirements and installation needs.

Choosing the right type depends on the specific demands of the space, ensuring optimal safety, durability, and performance.

Applications of Rubber Floor Sheets in Various Industries

Rubber floor sheets are incredibly versatile and have become a staple across a wide range of industries due to their durability, safety features, and adaptability. From high-traffic commercial spaces to specialized healthcare environments, these sheets are tailored to meet the demands of different settings. Here’s a closer look at where and how rubber floor sheets are used and why they are such an excellent choice for these applications.

1. Gyms and Fitness Centers

Gyms and fitness facilities leverage the shock-absorbing and non-slip properties of rubber floor sheets to create safe and effective workout environments.

- Why Rubber Works:

Rubber’s cushioning absorbs impact, protecting both users and the subfloor from dropped weights or intense exercise routines. Its slip-resistant surface minimizes accidents during high-intensity activities, even when sweat or moisture is present.

- Practical Applications:

- Weightlifting zones and free-weight areas benefit from thick rubber sheets to withstand constant impact from heavy equipment.

- Cardio sections use rubber flooring to reduce noise and provide a stable surface for equipment like treadmills.

- Group fitness rooms incorporate rubber mats for their durability and seamless installation, suitable for yoga, aerobics, or dance classes.

2. Industrial Facilities

Rubber floor sheets are a go-to solution in industrial settings, offering protection, resilience, and safety in environments subjected to extreme stress.

- Why Rubber Works:

Industrial facilities require flooring that is resistant to wear and tear, chemicals, and abrasions. Rubber’s durability and shock-absorbing properties make it ideal for areas with heavy machinery and forklifts.

- Practical Applications:

- Assembly lines use rubber sheets to reduce operator fatigue by cushioning repetitive impacts, improving worker productivity.

- Storage zones and loading docks rely on rubber flooring to prevent surface damage from machinery and inventory movement.

- Oil-resistant rubber sheets are installed in workshops to ensure safety in greasy or chemical-rich areas.

3. Healthcare and Laboratories

The healthcare and lab sectors demand flooring that can meet strict hygiene and safety standards, and rubber floor sheets rise to the challenge.

- Why Rubber Works:

Rubber sheets provide a non-slip, antimicrobial surface that resists stains, making them an excellent option for sterile and moisture-prone environments. Additionally, their shock absorption helps reduce noise levels, vital in healthcare settings where tranquility is critical.

- Practical Applications:

- Operating rooms and labs utilize non-porous rubber sheets that resist liquid penetration, ensuring easy disinfection.

- Patient rooms incorporate rubber flooring for its cushioning, softening patient walking surfaces and reducing slip risks.

- Pharmaceutical labs choose rubber flooring for its resistance to spills and harsh cleaning agents.

4. Retail and Commercial Spaces

Retail stores and commercial facilities favor rubber flooring for combining durability with aesthetic adaptability, ensuring functionality without sacrificing design.

- Why Rubber Works:

Rubber floors handle heavy foot traffic with ease, protecting against wear and tear. Their customizable textures and colors also allow them to match brand aesthetics, ensuring a cohesive and professional appearance.

- Practical Applications:

- Shopping mall walkways feature rubber sheets for their durability and ability to absorb sound, creating a quieter shopping experience.

- Restaurant kitchens use rubber mats with anti-fatigue properties to support workers during long shifts.

- Office lobbies install textured rubber flooring to provide a modern aesthetic with slip-resistant safety.

5. Home Environments

Rubber floor sheets have made their way into residential spaces, offering comfort, safety, and practicality for various uses.

- Why Rubber Works:

Rubber flooring provides homeowners with a durable, easy-to-clean surface that’s ideal for high-traffic or specialized areas of the home. It’s also a great solution for families looking for safety features in play areas or outdoor spaces.

- Practical Applications:

- Outdoor patios and garages use rubber sheets due to their weatherproof properties and resistance to oil or grease spills.

- Playrooms and nurseries utilize soft rubber flooring to minimize injury risks for children while providing a comfortable surface for crawling or playing.

- Home gyms feature rubber mats for their cushioning and noise-dampening qualities, enabling intense workouts without disturbing others in the house.

Summary

Rubber floor sheets cater to the unique demands of various industries with their durability, safety features, and adaptability. Whether it’s gyms looking for shock absorption, industrial facilities needing chemical resistance, or healthcare spaces prioritizing hygiene, rubber flooring delivers unmatched utility. Their ability to combine functionality with comfort and aesthetics ensures they remain a top choice for diverse applications, from commercial ventures to home improvement projects.

Installation Tips for Rubber Floor Sheets

Properly installing rubber floor sheets is essential to ensure their durability, safety, and aesthetic value. Whether you’re working on a small project or an extensive facility, following the right steps can make the difference between a professional-quality result and a poorly finished job. Here’s a detailed guide to help you achieve a successful installation.

1. Pre-Installation Preparation

Before starting the installation process, preparation is key to avoiding mistakes or delays.

- Measure the Area: Start by accurately measuring the space to determine how much material you’ll need. Account for any extra material required for cutting to fit corners or irregular shapes.

- Clean the Subfloor: Ensure the subfloor is clean, dry, and level. Remove dirt, dust, grease, or moisture that could interfere with the bonding process. Use a vacuum or mop to clear debris thoroughly.

- Inspect the Rubber Sheets: Unroll the rubber sheets and inspect for any defects or irregularities. Allow them to acclimate to room temperature for at least 24 hours, as this reduces shrinkage during installation.

2. Cutting and Fitting Techniques

Rubber floor sheets often need to be trimmed to fit the exact size and shape of the area, especially for corners and edges.

- Use the Right Tools: A utility knife with a fresh blade or a heavy-duty guillotine cutter works best for precise cuts. Always cut on a hard surface to avoid damaging the subfloor beneath.

- Measure Twice, Cut Once: Use a measuring tape and a straightedge to outline your cuts. Double-check measurements before making any cuts to avoid wasting material.

- Allow for Expansion: Maintain a small gap (1/8 inch) around the perimeter of the space to accommodate expansion and prevent buckling over time.

Example: For irregular spaces like a garage, paper templates can be created for tricky corners to ensure a precise fit before cutting the rubber sheets.

3. Adhesive Guidelines

Adhesives are crucial for securing the rubber sheets and ensuring they don’t shift during use.

- Choose the Right Adhesive: Use adhesives recommended by the manufacturer of the rubber floor sheets. For most installations, water-based adhesives work well and are easier to apply.

- Apply Evenly: Spread adhesive evenly with a notched trowel for a strong bond. Avoid over-applying, as excess adhesive can seep out during installation and create a mess.

- Work in Sections: Apply adhesive in manageable sections to ensure that it doesn’t dry out before the rubber sheet is positioned.

Pro Tip: If you’re working in a large area, consider using double-sided tape along the edges and seams for additional stability.

4. Achieving a Seamless Installation

A seamless appearance not only improves aesthetics but also minimizes hazards like tripping.

- Align the Sheets Carefully: Place the rubber sheets side by side, ensuring the edges meet without overlapping. Press seams together firmly to create a smooth, continuous surface.

- Roll the Floor: Use a 100-pound flooring roller to apply consistent pressure across the sheets. This ensures full adhesion and eliminates air bubbles beneath the surface.

- Seal the Joints: For a polished, waterproof finish, use silicone sealant or joint tape to seal the seams, especially in areas prone to moisture, such as gyms or kitchens.

Example: Fitness centers often use seamless installation techniques to create a professional-grade look and smooth transitions between zones.

5. DIY vs. Professional Installation

While some installation projects can be effectively handled as DIY, others may require professional expertise.

- When to DIY:

- Small spaces, e.g., home gyms or garages, with straightforward layouts.

- Projects using modular rubber tiles or pre-cut sheets that don’t require adhesive.

- When to Hire Professionals:

- Large, high-traffic spaces like commercial gyms or industrial facilities.

- Projects with irregular layouts or where detailed cutting and adhesive work are necessary.

- Floors requiring intricate seam sealing for a waterproof finish.

Professional installers bring experience and the right tools to ensure durability and precision, especially for complex or large-scale projects.

Final Thoughts

Installing rubber floor sheets can be an efficient and cost-effective project when done correctly. By thoroughly preparing the space, cutting materials precisely, applying adhesive carefully, and knowing when to bring in a professional, you’ll create a durable and seamless surface tailored to your needs. Whether upgrading a fitness center, industrial area, or home, these tips will help you achieve a high-quality result that lasts for years.

Maintenance Guidelines for Rubber Floor Sheets

Proper maintenance is essential for extending the lifespan and preserving the functionality of rubber floor sheets. With the right care routine, these durable surfaces can provide a safe, clean, and professional appearance for years. Here’s a detailed guide to maintaining rubber floor sheets, ensuring they remain in excellent condition.

1. Daily Cleaning Routines

Regular cleaning is the foundation of any maintenance plan. Daily upkeep prevents dirt, dust, and debris from accumulating, which can cause surface damage over time.

- Sweep or Vacuum: Use a soft-bristle broom or a vacuum with a non-beater bar attachment to remove dirt and grit.

- Spot Cleaning: Wipe up spills immediately using a damp cloth to avoid staining or moisture buildup.

- Dry Mop: For spaces like gyms or industrial areas, a dry microfiber mop can help pick up fine dust particles without scratching the surface.

Example: Gym owners often schedule daily vacuuming of high-traffic areas to maintain a clean, debris-free environment for users.

2. Deep Cleaning Methods

To address built-up grime that daily cleaning might miss, perform deep cleaning periodically to keep your rubber floor sheets looking their best.

- Use a pH-Neutral Cleaner: Avoid abrasive or highly alkaline cleaners, as they can damage the rubber. Mix a pH-neutral cleaner with warm water for effective yet safe cleaning.

- Mop Gently: Use a damp mop to clean the entire surface, ensuring it’s not oversaturated. Standing water can seep into seams and compromise adhesion.

- Rinse with Clean Water: After mopping, rinse the floor with clean water to remove any residue, preventing a slippery finish.

- Allow to Air Dry: Ensure the area is properly ventilated and allow the surface to air dry completely before use.

Pro Tip: For outdoor rubber floors, a pressure washer (on a low setting) can be used for deep cleaning, provided the sheets are securely installed.

3. Preventive Measures to Avoid Wear and Tear

Taking proactive steps can significantly minimize damage and ensure your floor maintains its original appearance and performance.

- Use Furniture Pads: Place protective pads under heavy equipment or furniture to prevent dents and scrapes.

- Rotate High-Traffic Areas: Consider rearranging workout zones or industrial equipment periodically to evenly distribute wear.

- Avoid Harsh Chemicals: Skip ammonia-based cleaners or solvents that can degrade the rubber over time.

- Post Clear Guidelines: Encourage users to avoid wearing sharp or hard-soled shoes that might leave marks.

Example: Commercial kitchens often use mats over rubber flooring in high-traffic prep zones to reduce wear and tear while maintaining safe footing.

4. Reconditioning Rubber Floor Sheets

Over time, rubber floor sheets may lose their original shine or develop minor scuffs. Reconditioning can restore their appearance and functionality.

- Polish the Surface: Apply a water-based rubber floor polish to restore a glossy finish and shield against stains.

- Buff for Smoothness: Use a low-speed mechanical buffer to even out the surface and remove light scratches.

- Repair Minor Damage: Fill in small cracks with rubber repair sealant to prevent further deterioration.

Pro Tip: Always test products like polishes or sealants on a small, inconspicuous area to ensure compatibility with your specific type of rubber floor.

5. Common Mistakes to Avoid

To maximize the life of your rubber floor sheets, steer clear of these frequent maintenance errors.

- Using Abrasive Tools: Avoid steel wool, stiff brushes, or abrasive cleaners that can scratch or damage the surface.

- Over-Wetting the Floor: Excess water can seep into seams and compromise the adhesive, especially for non-seamless installations.

- Skipping Regular Maintenance: Allowing dust and debris to accumulate can create a gritty surface that erodes the rubber over time.

- Using Bleach or Harsh Chemicals: These can discolor or weaken the material, reducing its durability.

Example: A common mistake in gyms is cleaning rubber floors with bleach, which can strip away the protective coating and cause long-term damage.

Final Thoughts

Maintaining rubber floor sheets doesn’t have to be challenging. By following a consistent cleaning routine, taking preventive measures, and reconditioning surfaces as needed, you can ensure their longevity and functionality. With proper care, rubber floor sheets will continue to provide the safety, durability, and aesthetic value that make them a standout choice across various spaces.